- #ALTIUM PCB DESIGN RULES VERIFICATION#

- #ALTIUM PCB DESIGN RULES SOFTWARE#

There are many other standards that affect design, manufacture, and qualification of printed circuit boards, but not all of these are critical for PCB designers.

IPC-1752A: Material Declaration Management standard defines reporting formats for data exchanged between designers, distributors, and manufacturers. Component manufacturers use these specifications when designing their land patterns to ensure solderability and reliable electrical connections. IPC 7351: Specifies footprint and land pattern requirements for SMT components. IPC-A-600 series: Defines acceptance metrics for printed circuit boards, as well as the three standard IPC Classes for various printed circuit board assemblies. The related IPC 6013 standard applies the same ideas to flex circuit boards. IPC 6012: Defines generic performance requirements as compiled from IPC 2221, IPC 4101, and other quality requirements. IPC 4761: Covers design guidelines for via protection to ensure reliability, manufacturability, and quality. IPC 2152: A newer standard that defines current carrying requirements in copper traces and planes in a number of different applications. IPC 4101: Defines material requirements for PCB laminate materials and other materials used to build stackups. IPC 2221: Establishes some generic design and performance requirements in PCBs and other forms of component mounting or interconnecting structures. Some of the important IPC design standards include: In addition, each standard is a very long document that includes a range of requirements for designers, manufacturers, or both. There are many sections of the IPC standards, and not all sections are applicable to every circuit board design. What IPC Sections are Relevant to PCB Design and Manufacturing? Some examples include via and microvia manufacturing, solder joint strength requirements, solder mask material and thickness, material properties for substrates, and several other manufacturing requirements. #ALTIUM PCB DESIGN RULES SOFTWARE#

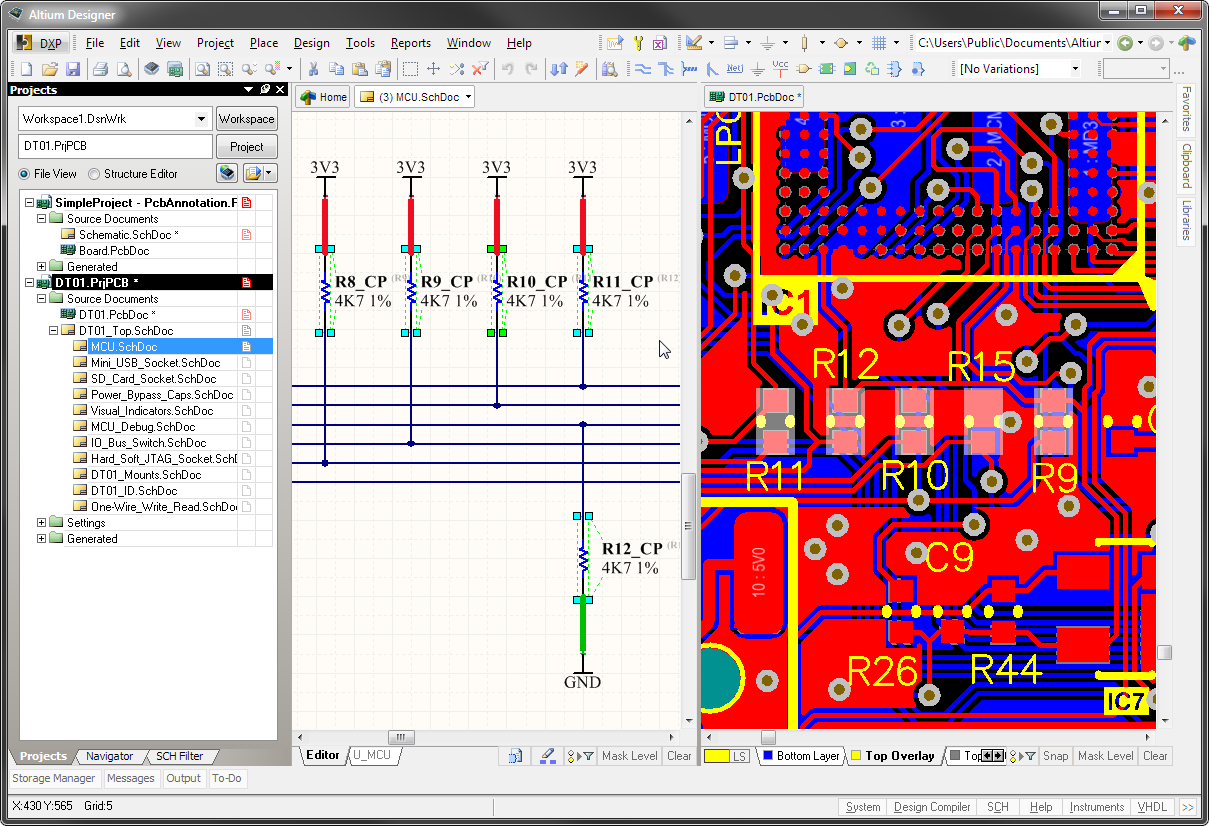

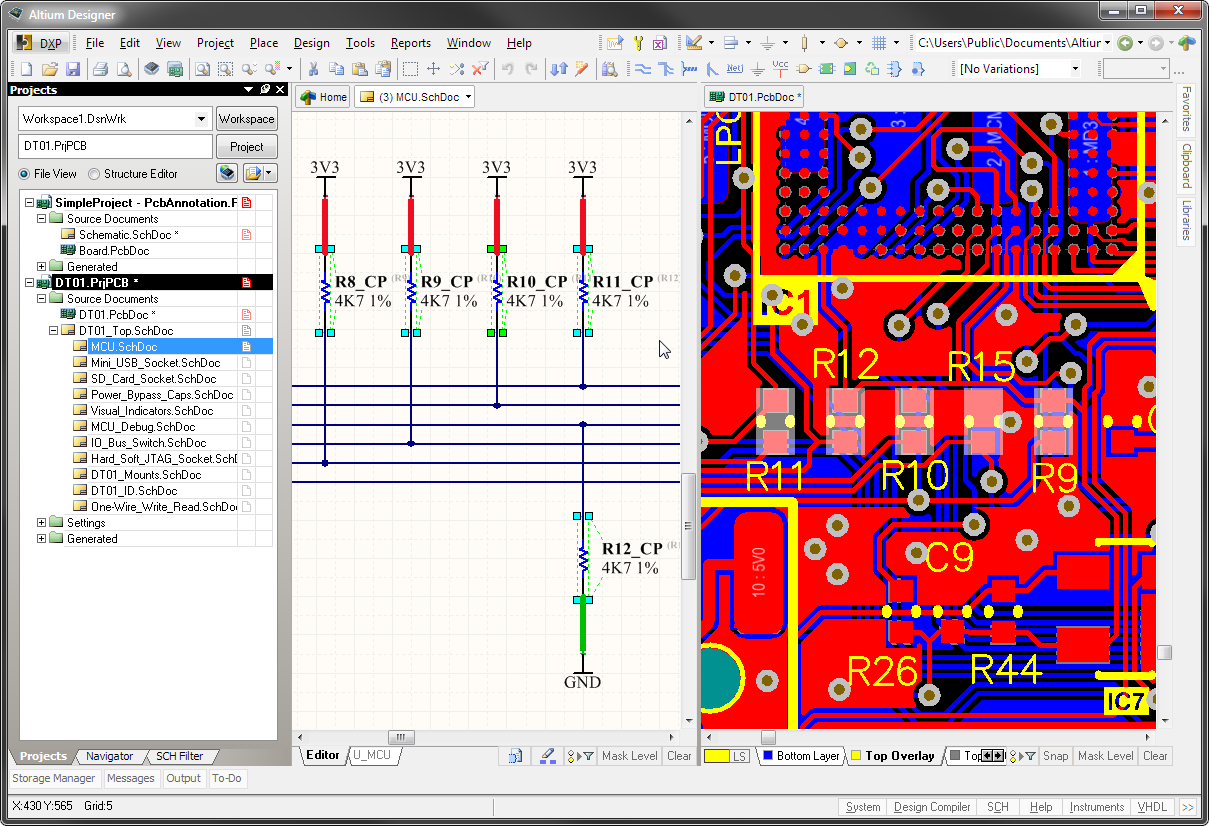

These manufacturing requirements ultimately translate back to design requirements, and designers need PCB design software to help ensure their boards will be compliant with IPC design requirements. The IPC standards include multiple manufacturing requirements for all aspects of a printed circuit board. IPC Standards on PCB Design and Manufacturing Altium Designer’s integrated design rule engine lets you define important IPC standards as design constraints, which helps you comply with these important standards. When you use the right design software with integrated compliance tools, it may be easier than you think to comply with IPC standards and design to different IPC product classes. If you are a PCB designer, there are some very important standards with which you should become familiar.

Very few people have ever read the entirety of the IPC standards, simply due to their breadth and depth. No matter which industry you work in, IPC likely defines standards that specify important requirements for your products. The goal of the IPC standards is to ensure that electronics products are reliable, safe, and manufacturable. These industry standards are designed to ensure the reliability and manufacturability of printed circuits and other electronic assemblies.

#ALTIUM PCB DESIGN RULES VERIFICATION#

The only unified PCB design suite with design and verification features that can be tailored to IPC standards.Īmong the many electronics standards organizations, the organization that all designers should be aware of is IPC.

0 kommentar(er)

0 kommentar(er)